The X-Press Lift Tool products below are grouped to address the three trucking markets we have developed safe and efficient products for: 1) large tractor/trailers and the task of cranking the landing gear manually to connect and disconnect trailers; 2) grain hopper trailers and the opening and closing of hopper doors; 3) raising and lowering goose neck, dump and utility trailers. Eliminating the cranking currently done will get the driver doing what he/she does best – driving while also being better rested. Normally but especially during extreme hot, cold, rainy and other inclement weather this task is unpleasant at best.

The products to address each market are separated into the three groups identified above with the tractor/trailer products shown initially. There are two additional tabs labeled “Grain Trailer Products” and “GooseNeck, Dump, Utility Trailer Products” to show the specific products that address those markets.

Products

Tractor/Trailer Products

1. XLT Trailer Drill Kit

Above is the XLT Trailer Kit. The XLT proprietary mechanism (drill like) is lithium battery powered, making it portable and powerful. The XLT must produce high torque to be effective when dealing with the landing gear. The other components of the kit are: charger, battery, coupler, latch pin, and tool bag. Not shown is a pair of the TED straps – the base safety device to ensure no torque is transmitted to user during operation. There is one upgrade available: a 5AH battery using Samsung internals vs the standard 4AH battery.

2. T-Coupler + Latch Pin

This specialty product connects to the landing gear crank shaft to raise and lower the trailer after the handle has been removed. A latch pin is retained on the shaft which the coupler connects to allowing for the XLT drill to raise or lower the trailer. (included in the kit)

3. TED Straps

The straps are attached to the handles of the drill. Connectors are then attached to the trailer via the sidewall or a frame support is one use of the straps. The other use is stepping onto the strap loop on the ground and the user’s weight controlling the torque. Both methods prevent the drill from spinning due to the torque and thereby allows for safe use. This is typically used as a temporary solution – fleet installation is the preferred method of XLT System use. (included in the kit)

4. TED Drill Plate

Shown is the XLT DRILL with a TED drill plate bolted onto it. This plate has rods projecting from it which will be inserted into one of the TED Trailer Plate mounts (identified below) which are permanently attached to the trailer. When used properly will eliminate any torque generated ensuring safety first, quick to use and getting the driver on the road rested due to no cranking needed.

5. TED Trailer Bar

The Trailer Bar is part of the TED product line made specifically for a model of trailer. There are two holes on the bar which will have the rods on the Drill Plate inserted into it to eliminate the torque as the coupler is slid over the trailer leg shaft. A 10-15 minute installation is all it takes to make your use of the XLT SYSTEM safe and allowing for the driver to do what he does best -drive.

6. TED Trailer Plate I-Beam and Handle Hangar Mount

The most common TRAILER TED SOLUTION. This TED trailer safety product consists of a kit made specifically for trailers with I-Beam flooring supports (easily the majority). The trailer I-Beams have clamps and flat steel to suspend the TED trailer plate around the landing gear shaft using a horizontal bar to prevent any torque transmission to the user. Quick, 5 minute install after trailer handle is removed, makes fleet installation rollout easy and pain free. Kit parts are: TED Trailer Plate, pair of I-Beam clamps, trailer plate bar, connecting nut/bolt sets, two flat steel mounts, handle hangar, square and semi-circle (not shown) latch pin. XLT SYSTEM fleet installation is now a breeze with the TED Trailer I-Beam option and the trailer bar. The square latch pin secures the crank handle to the trailer either horizontally or vertically via the hangar supplied below the horizontal trailer plate bar.

7. TED Trailer Plate I-Beam

The most common TRAILER TED SOLUTION. This TED trailer safety product consists of a kit made specifically for trailers with I-Beam flooring supports (easily the majority). The trailer I-Beams have clamps and flat steel to suspend the TED trailer plate around the landing gear shaft using a horizontal bar to prevent any torque transmission to the user. Quick, 5 minute install after trailer handle is removed, makes fleet installation rollout easy and pain free. Kit parts are: TED Trailer Plate, pair of I-Beam clamps, trailer plate bar, connecting nut/bolt sets, two flat steel mounts, handle hangar, and semi-circle (not shown) latch pin. XLT SYSTEM fleet installation is now a breeze with the TED Trailer I-Beam option and the trailer bar.

Grain Trailer Products

1. XLT Grain Drill Kit

Shown is the XLT GRAIN KIT. The kit is comprised of: drill, charger, battery, and coupler. Not shown is the pair of TED straps and the tool bag. The XLT proprietary mechanism (drill like) is lithium battery powered to make it portable and powerful. The XLT must produce high torque to be able to open and close grain hopper doors. The sole upgrade option is a battery upgrade to 5AH (4AH being standard).

2. Grain Coupler

This coupler is a 6-point socket to connect to the hopper door shaft nut to open/close it. It is also used for the landing gear as well. This coupler is used by the Timpte brand of trailers along with several other brands. It has a set screw on it to ensure it will not detach from the XLT drill, making it semi-permanent. (included in the kit)

3. Grain Coupler Insert

This insert works with the 6-point socket to operate other grain trailer hopper doors. It resides in the 6-point socket to open/close grain hopper doors using the alternative square connector configurations. This allows for the 6-point socket to be semi-permanently attached to the XLT drill and allow for quicker changes when multiple trailer types are being utilized.

4. Grain TED

The GRAIN TED is adjustable up/down to connect with the left and right handles of the XLT drill which is connected to the hopper door shaft nut. This prevents the drill from spinning due to the torque generated by the XLT drill when needed by a stubborn hopper door. Your weight on the GRAIN TED’s base allows for a simple trigger pull to open or close the hopper door both safely and with no arm, shoulder or back strains.

5. TED Straps

The straps attach to the drill and an anchor point around the grain hopper door connector shaft. This will prevent the drill from spinning due to the torque generated by the high torque drill needed. The straps can also be on the ground with the user’s weight ensuring the XLT does not turn. A much better option is use of the Grain TED for it is quicker to use and no straps to contend with along with supplying a safer operation. (included in the kit)

GooseNeck, Dump, Utility Trailer Products

1. XLT Trailer Drill Kit

Above is the XLT Trailer Kit. The XLT proprietary mechanism (drill like) is lithium battery powered, making it portable and powerful. The XLT must produce high torque to be effective when dealing with the landing gear. The other components of the kit are: charger, battery, coupler, latch pin, and tool bag. Not shown is a pair of the TED straps – the base safety device to ensure no torque is transmitted to user during operation. There is one upgrade available: a 5AH battery using Samsung internals vs the standard 4AH battery.

2. T-Coupler + Latch Pin

This specialty product connects to the landing gear crank shaft to raise and lower the trailer after the handle has been removed. A latch pin is retained on the shaft which the coupler connects to allowing for the XLT drill to raise or lower the trailer. (included in the kit)

3. TED Straps

The straps are attached to the handles of the drill. Connectors are then attached to the trailer via the sidewall or a frame support is one use of the straps. The other use is stepping onto the strap loop on the ground and the user’s weight controlling the torque. Both methods prevent the drill from spinning due to the torque and thereby allows for safe use. This is typically used as a temporary solution – fleet installation is the preferred method of XLT System use. (included in the kit)

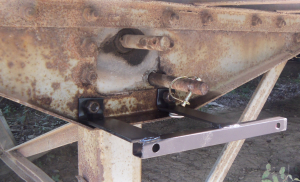

4. TED 4Square Kit

This TED kit supplies all the necessary components to ensure safety during use of the XLT DRILL. A strap is attached to each of the drill handles with clips. On the 4×4 trailer jack a u-bolt with straps and connectors has been attached permanently. After the coupler is placed on the trailer crank shaft the clips and connectors are snapped. When used properly this will eliminate any torque generated and is quick to use as well.